The following are required to install the Conflux 1 Furnace. Although not required, we recommend that the furnace and printer as complete system are installed in the same space for ease of use.

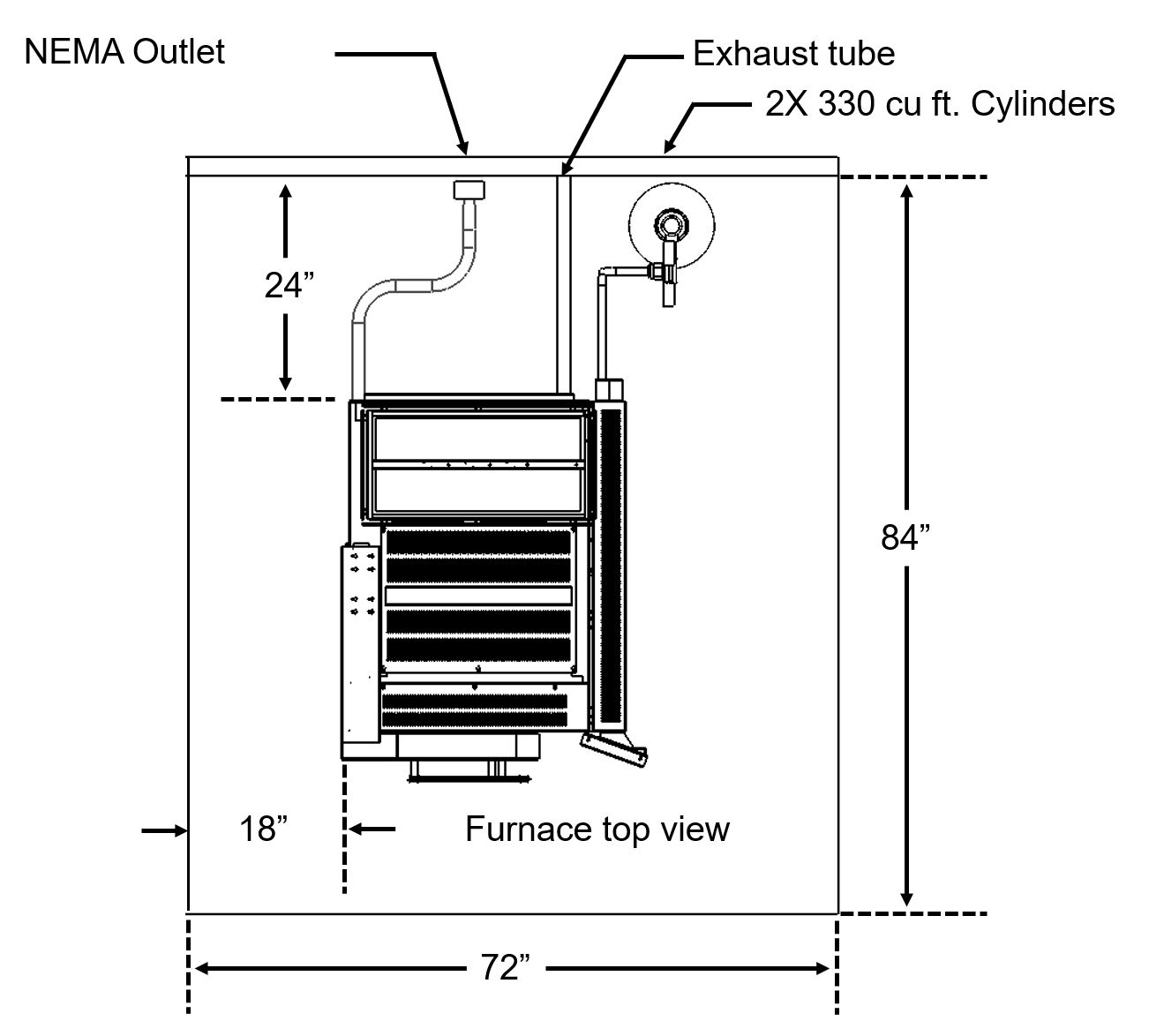

- Installation and operating space of 6' wide x 7' deep x 8' high for the furnace (see layout below).

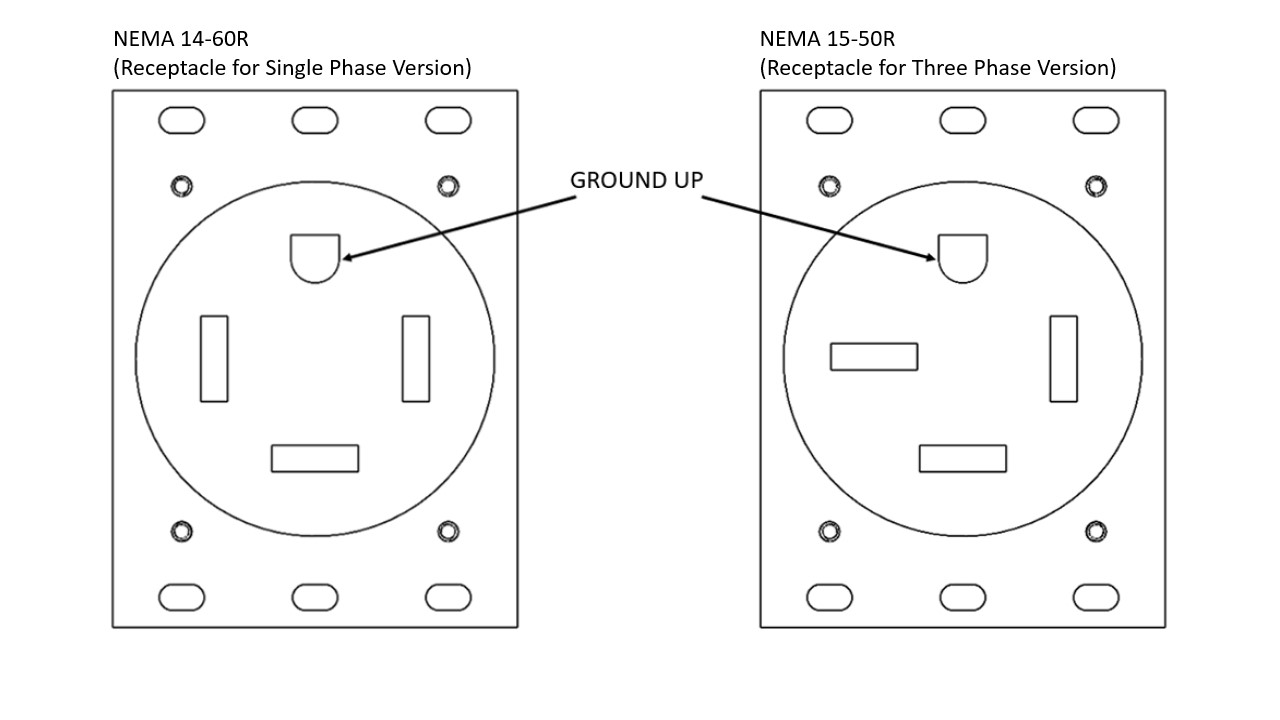

- For single phase machines: 1x NEMA 14-60R receptacle installed and wired. For three-phase machines: 1x NEMA 15-50R receptacle in North America. See Technical Parameters for more details on power requirements. The receptacle should be mounted with the ground pin at the top for optimal connection with the cord.

- A secure way to mount T size gas cylinders (2 cylinders for convenience). McMaster-Carr PN 2283T7 is recommended. See installation drawing above for location.

- T-size argon cylinder (UHP - 99.999% purity Ar).

- 3/4” or larger OD flame-resistant hose for venting the furnace atmosphere. This should extend to the furnace location – see drawing above for detail. It will be connected to a KF-25 exhaust fitting on the furnace. After a section of flexible hose, stainless steel pipe can be used to route the exhaust out of the building. Note that this exhaust can be flammable during debinding of heavy loads – see note in Flammability and Explosion.

- A combination gas and carbon monoxide detector such as the KN-COEG-3 should be installed near the furnace.

- A fire extinguisher should be located nearby.

- 1-1/8” wrench for connecting cylinders.

- Step ladder 1.8m (6’) minimum which can be used next to the installed location of the furnace for installation and service of heating elements.

- Heat resistant gloves for removing parts from the furnace at up to 200C (~390F).

- Non-combustible surface for placing tray with parts after sintering.