The XY calibration ensures that the two extruders are aligned in the X and Y dimensions. Ensure that both extruders have material loaded and run E1 and E2 Z Calibration before running the XY calibration.

| Required Tools for this Routine |

|---|

| Flexible Putty Knife |

| Paper Towel |

| Water |

¶

How-To

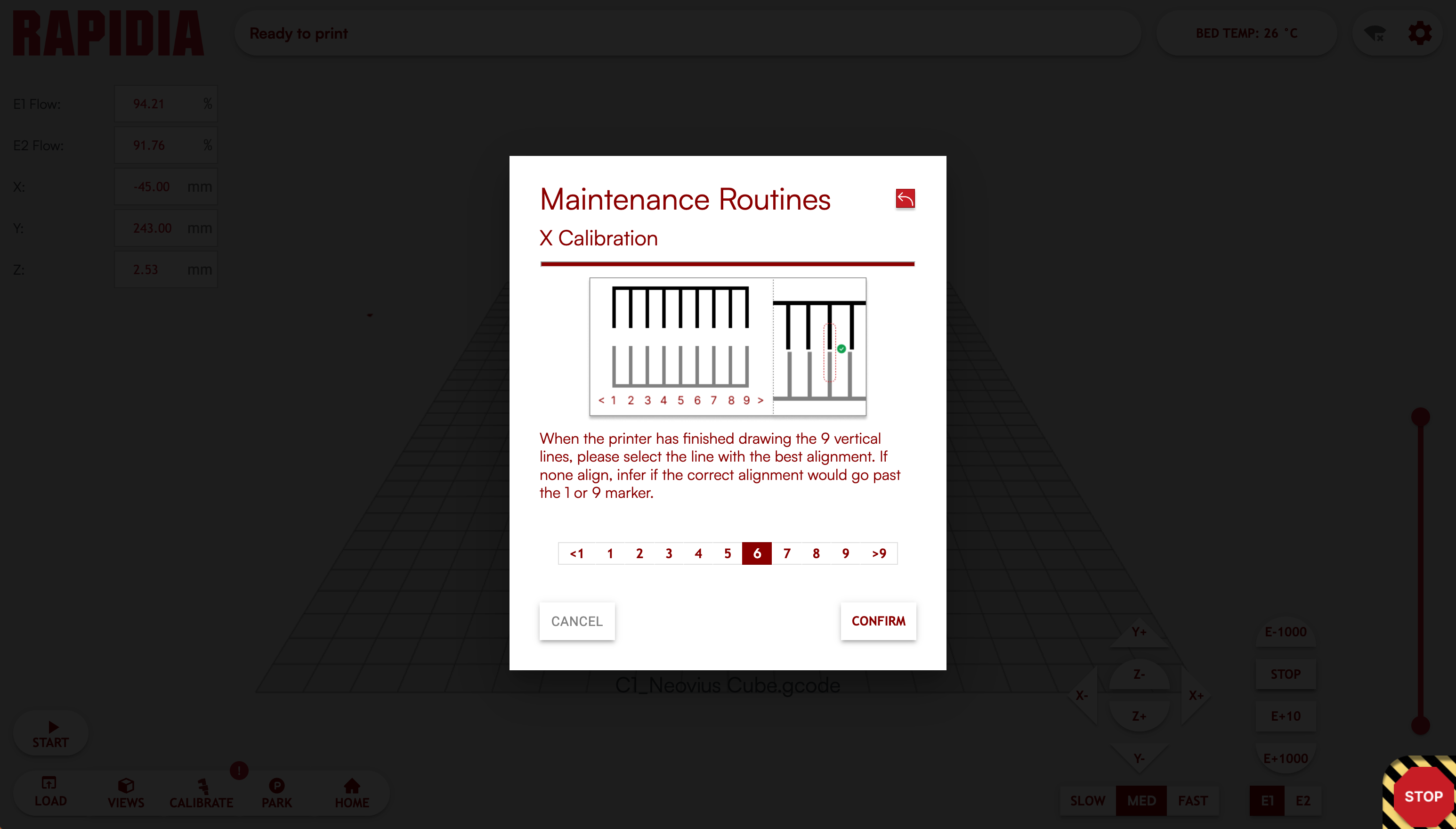

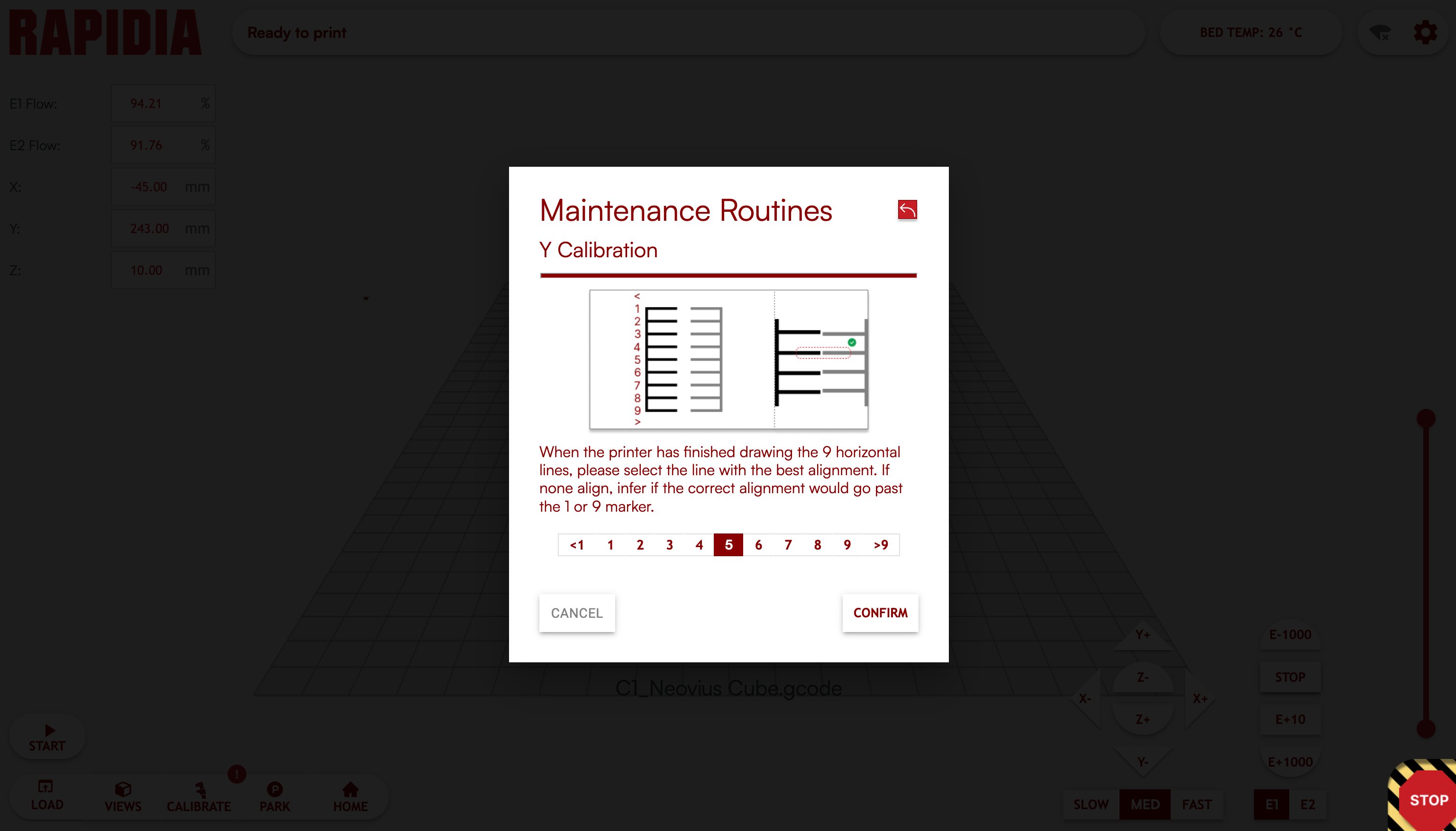

1. In Rapidia Host’s calibration menu, run the XY CALIBRATION and select the desired dimensions to calibrate. Ensure that the bed is clean before you click START.

2. After the line pattern is printed, use the calibration dialog to select which lines align the best. If none of the lines align, use the trend in the lines to infer if the correct alignment goes past the 1 or 9 marker.

3. If either the X or Y patterns are misaligned by much more than 1mm it is possible to change the alignment manually, measure the gap between the middle-most line (line 5) and finish the calibration. In the calibration menu, change the X and Y offsets by the amount measured between the middle lines. Increasing the X offset will move the metal lines towards the right of the print bed (towards extruder 2) and increasing the Y offset will move the metal lines toward the back of the printer. Run the calibration a second time to fine-tune the alignment.

4. If the lines are within 1mm continue to follow the alignment’s instructions, selecting the most appropriate option until good alignment is achieved.