Changing material cartridges on the Conflux 1 Printer is simple and can be done in just a view minutes.

To just reload the same material, view instructions here: Reloading Material.

Find out what feedstock Rapidia offers in Materials.

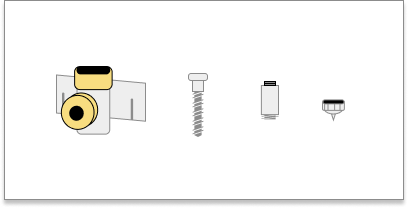

| Required Tools for this Routine |

|---|

| Cartridge Wrench |

| Wrench |

| Allen Key |

¶ How To

Spare paste extruders can be assigned to different materials types to expedite the process of changing material. If needed, additional paste extruders can be purchased from Rapidia. To ensure there is no contamination between materials, paste extruders that will be used with a new material should be thoroughly cleaned during material changes.

Revisit these sections if you are planning to reuse Paste Extruder and Paste Feed Hose:

¶ First Steps

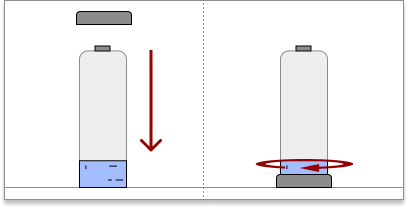

Turn off the charge pump by switching it off on the front control panel.

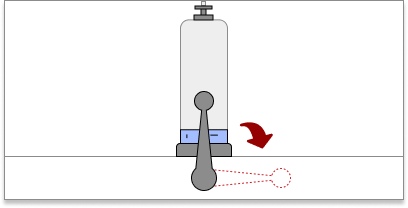

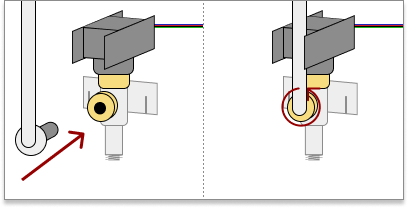

Depressurize Paste

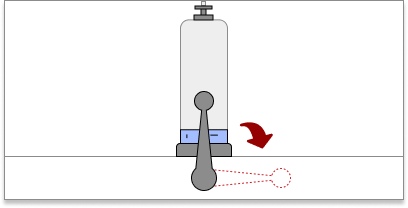

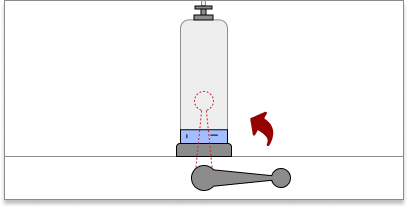

Slowly lower the relevant material selection levers to release the pressure in the cartridge. Water will “hiss” out of the cartridge.

WARNING: water splashing may occur while you do this. Please move water sensitive equipment and objects away before proceeding. Depressurize the paste canister by pulling the lever to a horizontal position.

Unplug Stepper Motor

Unclip and unplug the left stepper motor from the printer by disconnecting the 4 wire connectors.

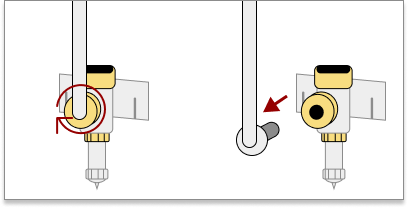

Unscrew Stepper Motor

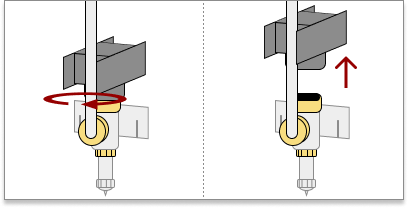

Unscrew the brass ring holding the stepper motor and remove the motor from the extruder body and set it safely aside.

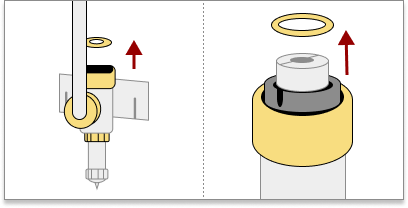

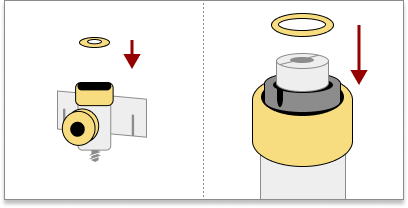

Remove Spacer Ring

Remove the spacer ring that was between the extruder body and the stepper motor. Please set it safely aside and take care not to lose it.

Remove Material Hose

Unscrew the extruder body from the hose and pull the head out. To prevent the material from drying out, please cover the hose and screw on its cap.

|

|

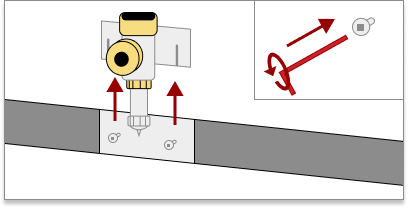

Remove Extruder

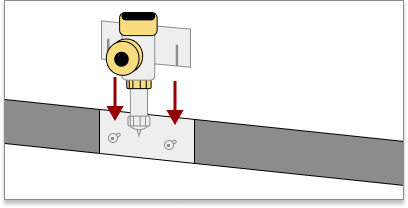

Use an Allen Key to loosen the screws (but do not remove them), and lift the extruder body off of the printer.

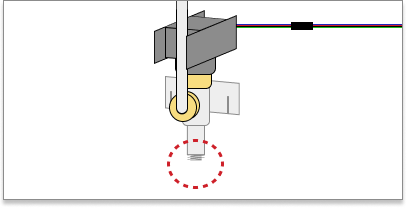

Unscrew the Nozzle

Unscrew and remove the nozzle from the extruder.

Unscrew the Retaining Nut

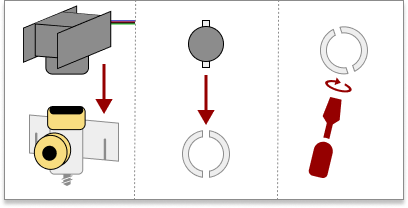

Unscrew and remove the retaining nut from the stator. You may need a wrench to unscrew it.

Remove the Stator

Unscrew and remove the stator from the extruder body. Use a screwdriver or your finger to hold the rotor in place from the top, otherwise, the stator will not unthread correctly.

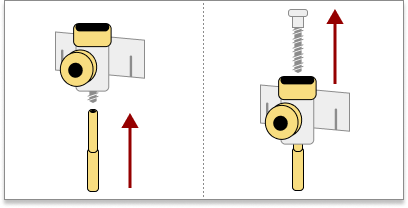

Remove the Rotor

Push the Rotor Removing tool up from below, and pop the rotor out from the top of the extruder.

Wash and Dry Parts

Wash the extruder body, rotor, stator, and nozzle with water and then dry them before proceeding.

WARNING: be mindful not to spray the rotor bearings while cleaning (The head of the rotor). It will displace lubricant and potentially seize the bearings.

Mount the Extruder

Place the extruder body back onto the printer body. After mounting the extruder, tighten the screws with an Allen Key.

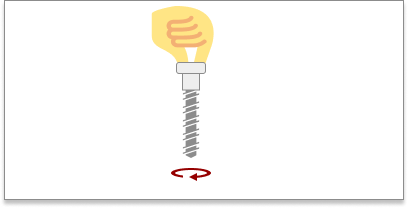

Test the Rotor's Bearings

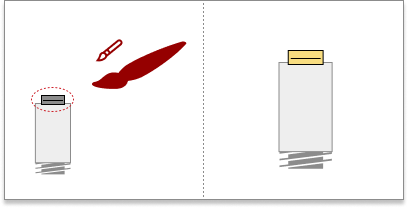

Verify that the rotors bearings are functional. Hold the top of the rotor and spin the shaft. If the shaft does not spin, replace the rotor with a new one.

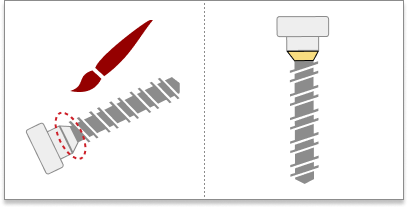

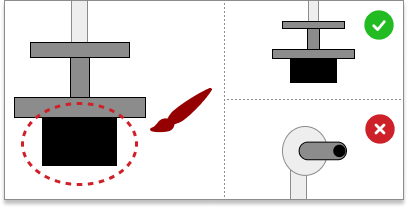

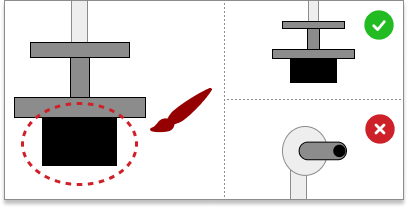

Lubricate the Rotor

Lubricate the rim at the bottom of the Rotor’s head with a brush. Try to get an even coating.

Attach the Rotor

Push the Rotor in from the top. You should feel the rotor click into the extruder body when secured.

Add Spacer Ring

Put the spacer ring back inside the extruder body on top of the rotor.

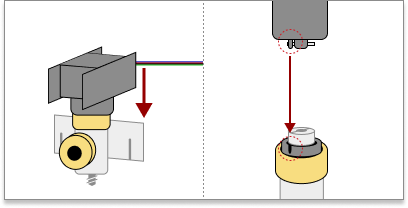

Align Stepper Motor

Place the stepper motor on top of the extruder body. Line up the stepper’s shaft pins with the Rotor’s slots. If you have any issues, you can use a flat-headed screwdriver to re-align the Rotor. Be sure to point the stepper motor's cables towards the inside of the machine, facing away from the front.

Align Stepper to Extruder

While keeping the Rotor and Stepper aligned, now align the stepper with the extruder body. Line up the stepper’s locating pin with the extruder body’s housing.

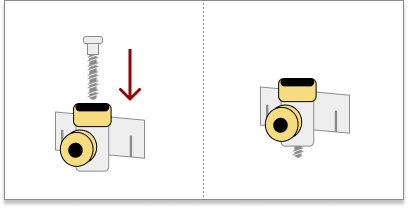

Attach the Stepper Motor

After aligning the stepper with both the extruder and the rotor, firmly screw the extruder onto the stepper.

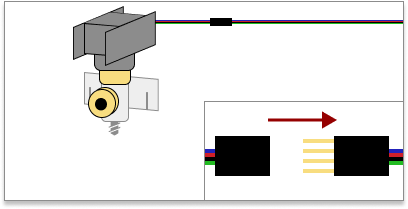

Plug In Stepper Motor

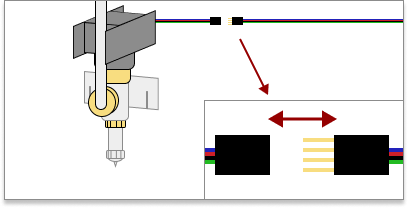

Plug in the stepper motor into the printer. Be sure to align the colors of the wires correctly.

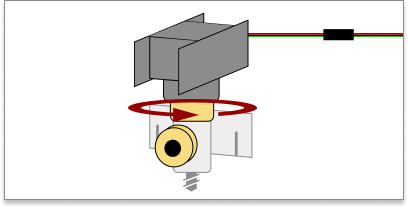

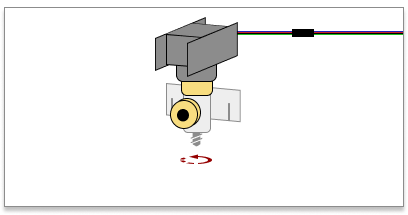

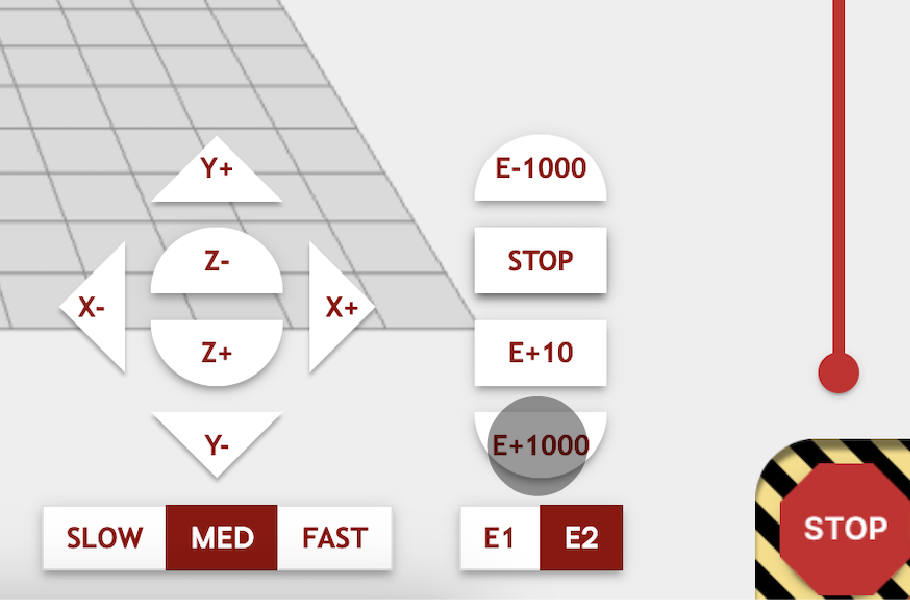

Verify the Stepper Motor

Verify that the Stepper Motor is rotating the Rotor. If not, please click ‘Restart’ to go back and fix your printer.

Lubricate the Stator

Lubricate the sides of the rubber ring at the top of the Stator with a brush. Try to get an even coating. Also apply water to the insides of the Stator, as this will make it easier to thread onto the extruder.

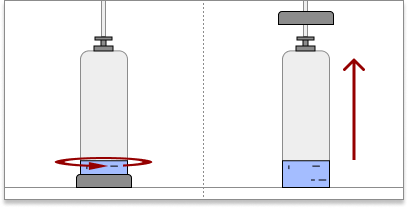

Attach Stator

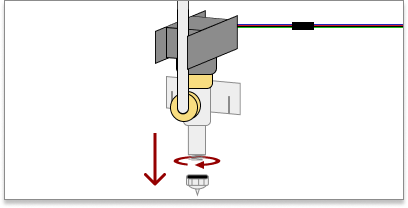

Start the stepper motor. While the rotor is spinning, slide the stator onto the rotor.The stator will begin thread itself, but continue to hold the stator up. When the stator no longer rises, stop the stepper.

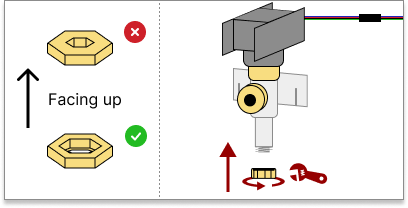

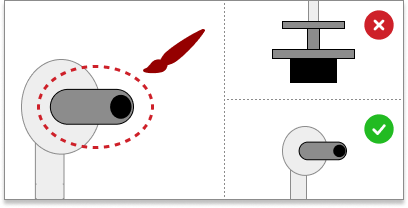

Attach Retaining Nut

WARNING: Be sure to orientate the nut correctly with the right side facing upwards. Put the retaining nut back on top of the stator and screw it back on. After tightening the nut on with your fingers, use a wrench and make a quarter turn to firmly secure the nut.

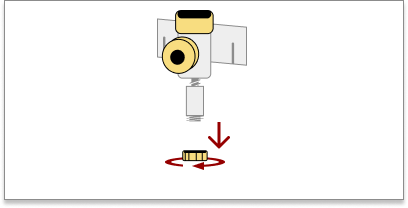

Remove the Holding Ring

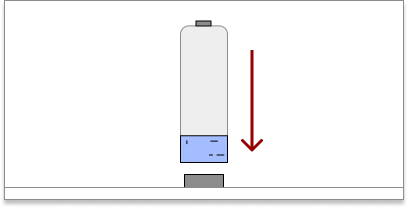

Unscrew and remove the holding ring at the bottom of the paste.

Remove the Paste

WARNING: water splashing may occur while you do this. Please move water sensitive equipment and objects away before proceeding. Remove the paste canister from the printer. To prevent as much splashing as possible slowly tilt the cartridge to one side and allow it to drain water out a small opening.

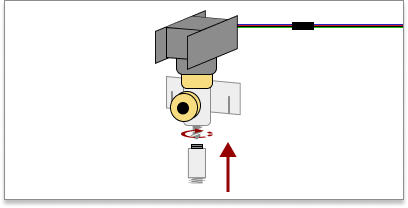

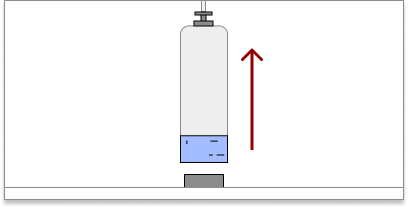

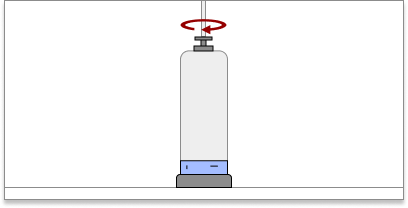

Load New Paste Canister

Place the new paste canister onto the printer.

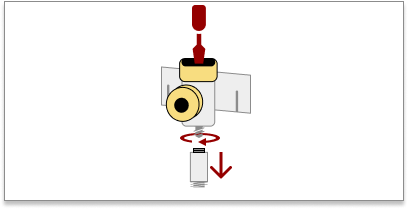

Lock the Holding Ring

Slide down the holding ring and then screw it in place to secure the paste.

Lubricate Hose Inlet

WARNING: Be sure to work on the right end of the hose. Lubricate the side of the hose inlet’s input. Try to get an even coating.

Lubricate Hose Outlet

Lubricate the side of the hose’s outlet plug. Try to get an even coating. Be sure to work on the right end of the hose.

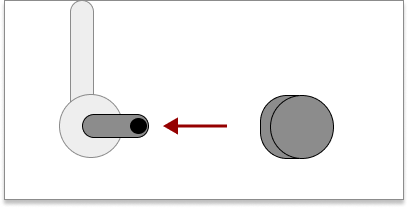

Attach the Hose Inlet

Plug in and screw on the hose inlet into the paste canister. Note, while attaching the inlet, you may want to position the hose towards the printer, so you can attach the outlet easier later.

Pressurize Paste

WARNING: water splashing may occur while you do this. Please move water sensitive equipment and objects away before proceeding. Pressurize the paste canister by pulling the lever to a vertical position. Wait until both the High and Low pressure dials on the printer stop rising.

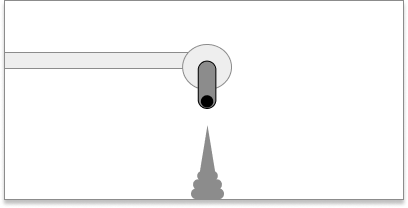

Purge Material from the Hose

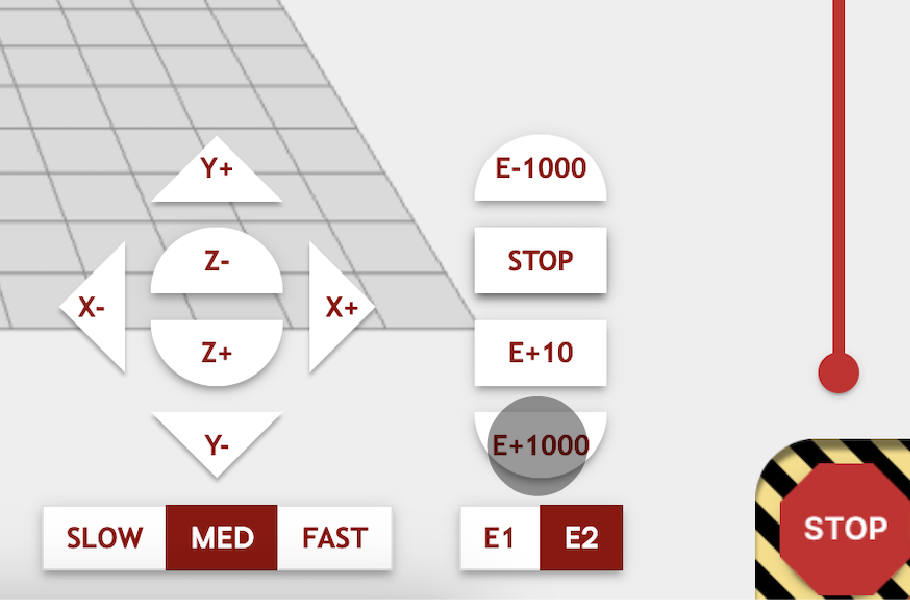

Begin removing air from the hose. Purge the material, until you see paste come out the outlet. Remember to pressurize your printer and flip the switch to activate the pump

Depressurize Paste

WARNING: water splashing may occur while you do this. Please move water sensitive equipment and objects away before proceeding. Depressurize the paste canister by pulling the lever to a horizontal position.

Lubricate Hose Outlet

Lubricate the side of the hose’s outlet plug. Try to get an even coating. Be sure to work on the right end of the hose.

Attach the Hose Outlet

Attach the hose outlet to the extruder body. Be mindful of the hose’s position and to keep it between the stepper motor’s arms.

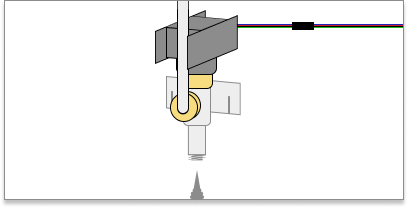

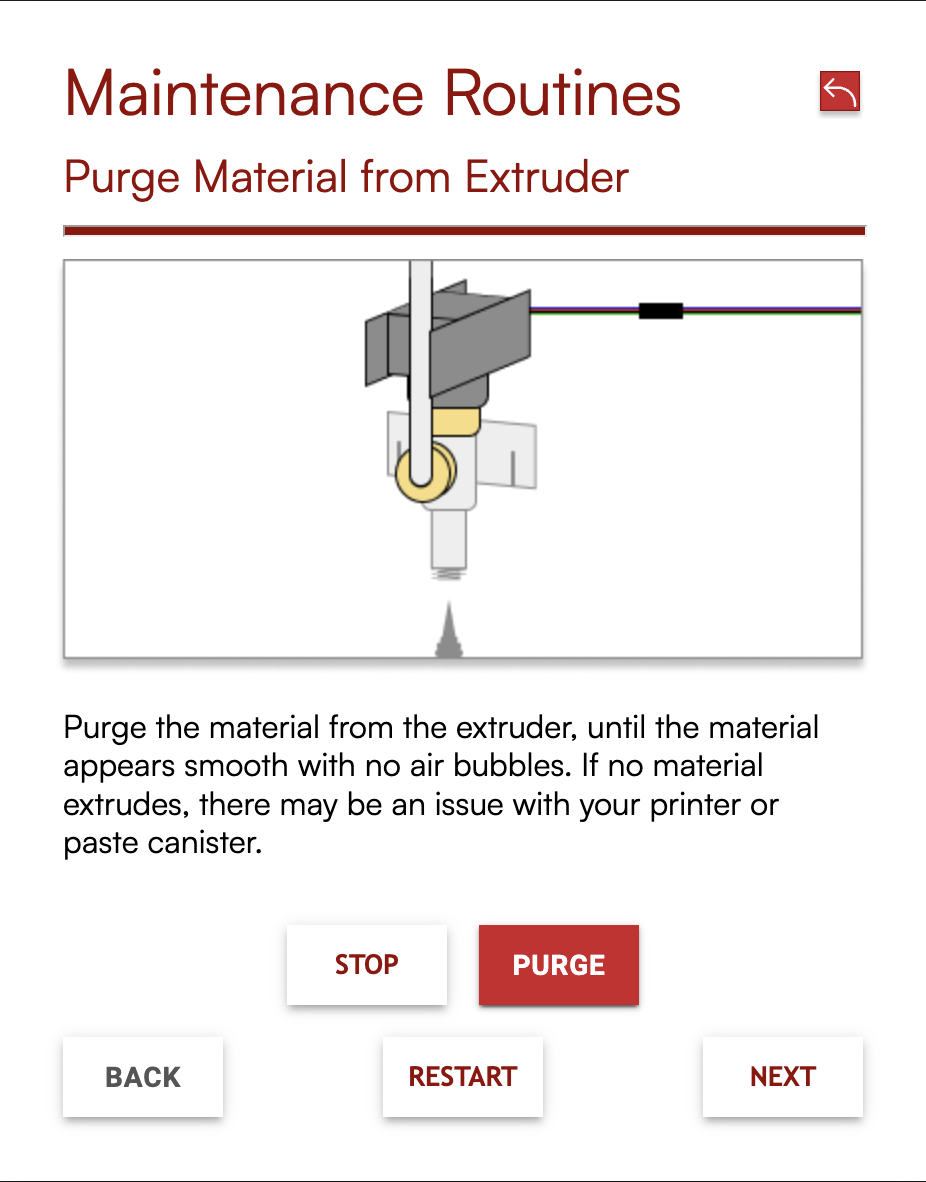

Purge Material from Extruder

Purge the material from the extruder, until the material appears smooth with no air bubbles. If no material extrudes, there may be an issue with your printer or paste canister.

maintenance routine for PASTE E1 / E2 |

respective paste extruder |

Clean Extruder

Clean the bottom of the extruder where the nozzle will go with a paper towel or cloth.

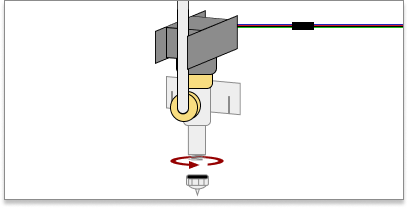

Attach Nozzle

Screw the nozzle onto the bottom of the extruder with your fingers and then make sure it’s firmly in place with a wrench.

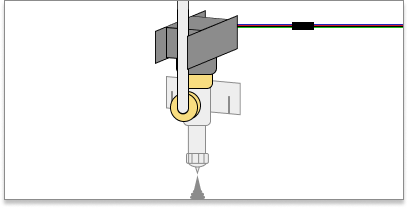

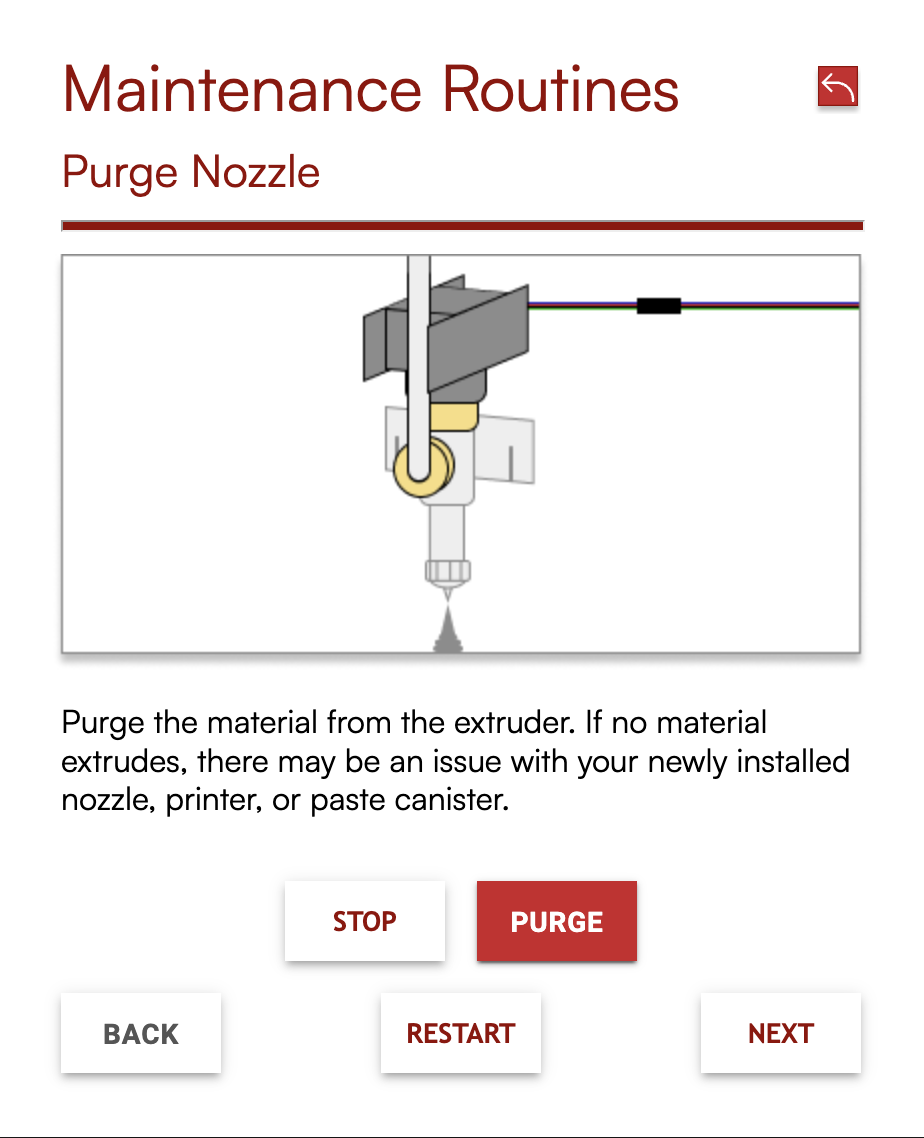

Purge Nozzle

Purge the material from the extruder. If no material extrudes, there may be an issue with your newly installed nozzle, printer, or paste canister.

maintenance routine for PASTE E1 / E2 |

respective paste extruder |